NET@PRO

MES / MOM

NET@PRO can manage distributed networks understood as plants belonging to the same group, company personnel that operates externally, clients, suppliers and subcontractors. In fact, the system lets you transfer and aggregate the data from every plant, supplier, and subcontractor so that it is available to the main office.

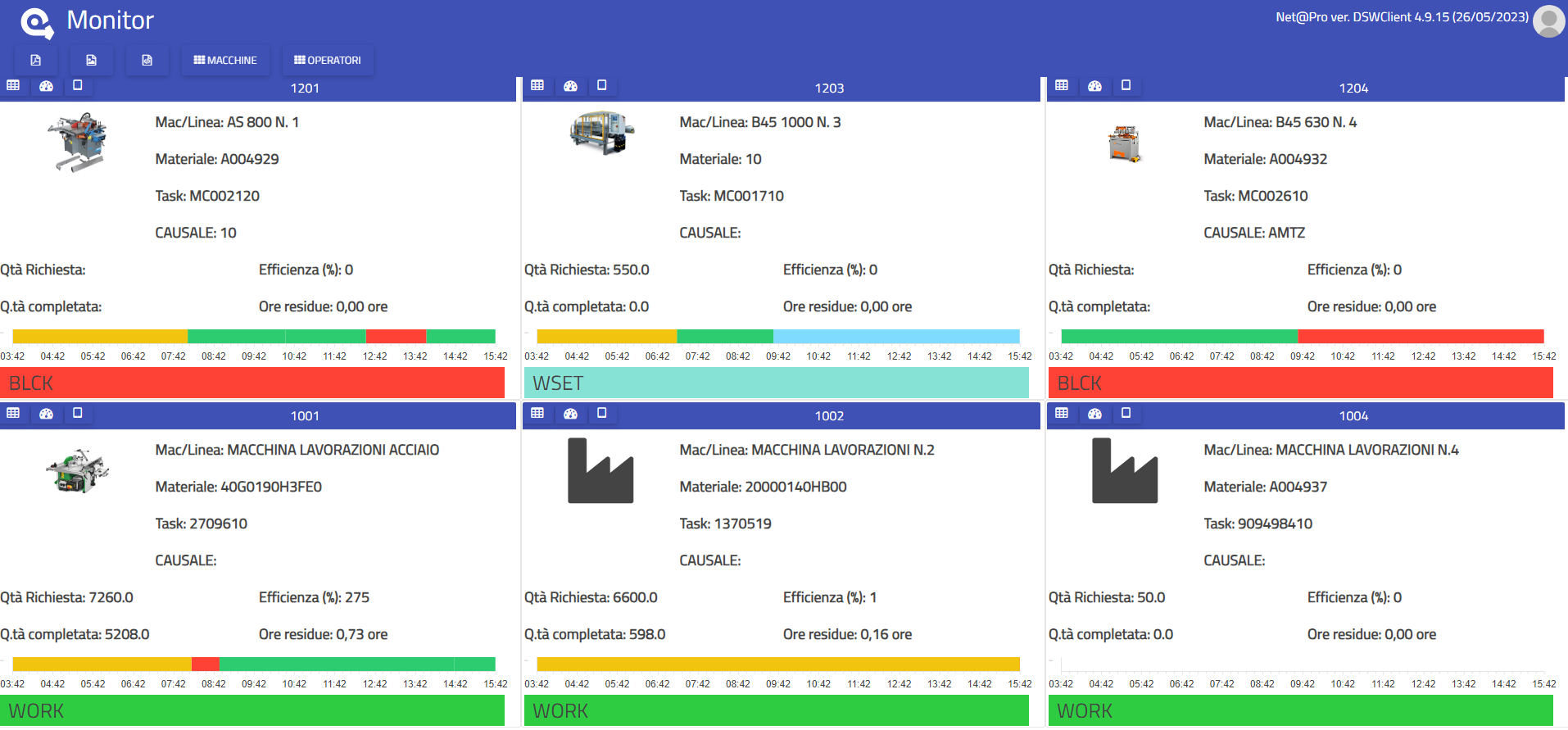

Monitoring and proactivity

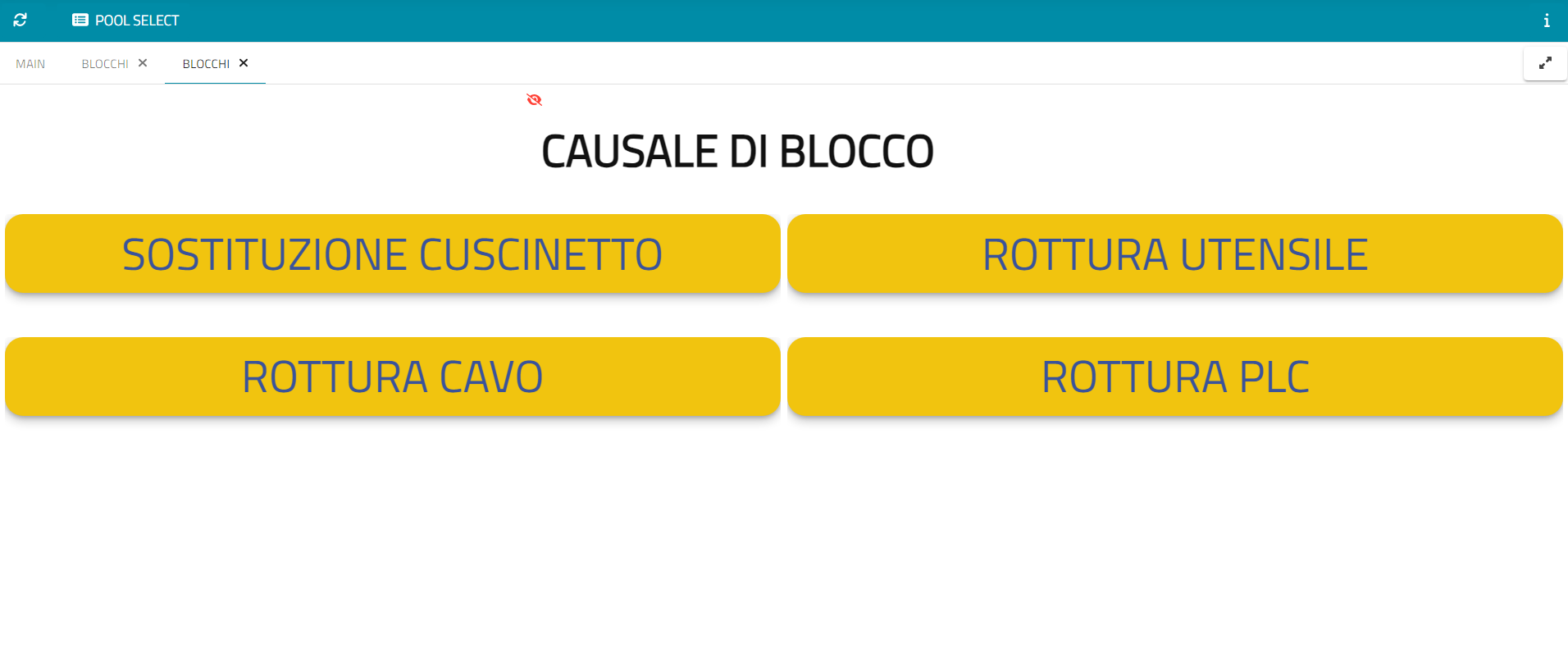

Compared to traditional data collection, the NET@PRO MES is able to report any production anomalies proactively and in real time (times that are too long, machine breakdowns, etc.), making it possible to immediately take action in the event of problems and avoid hazardous issues.

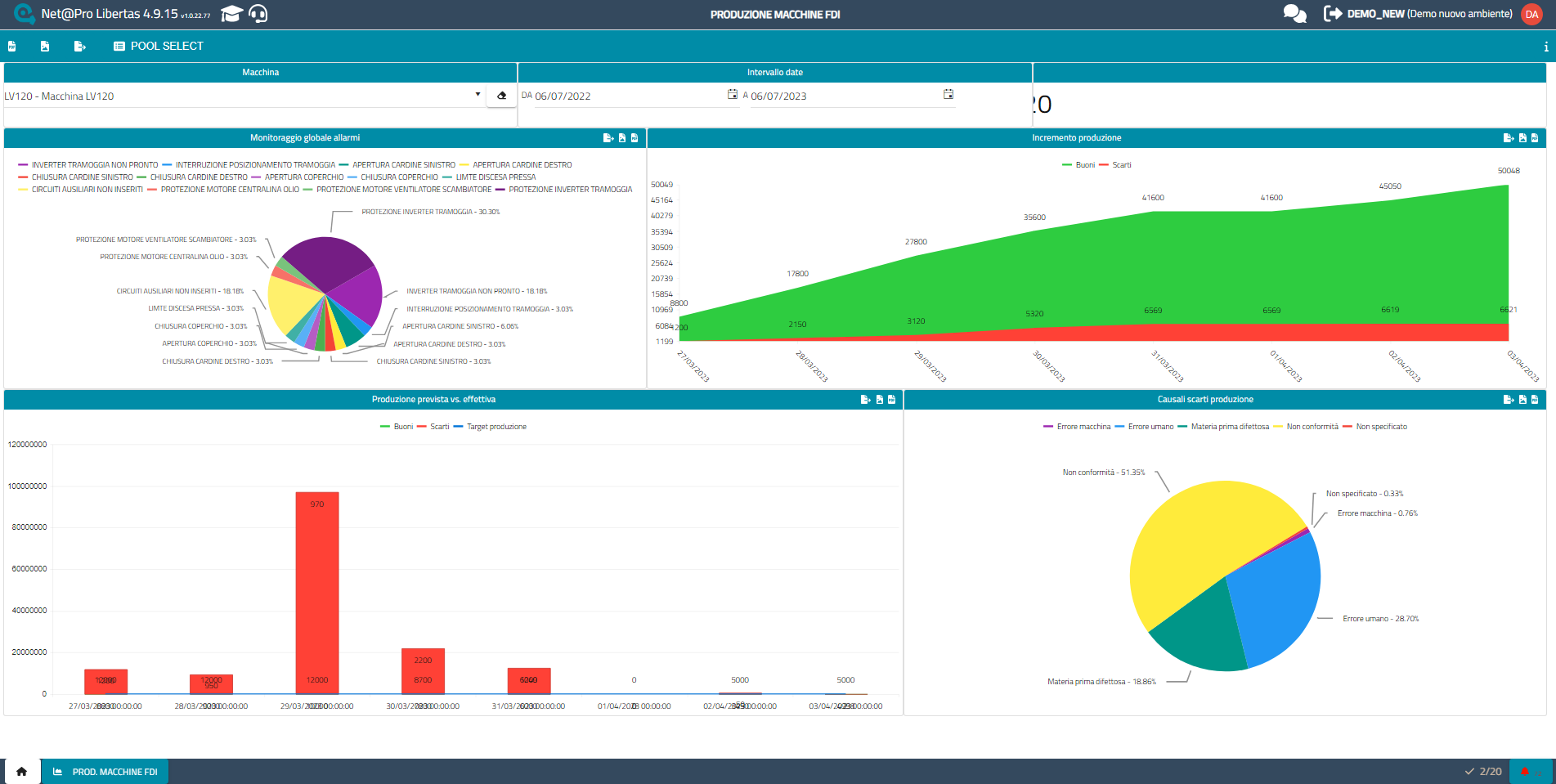

The NET@PRO MES is equipped with an FDI module that allows you to connect to production equipment and directly acquire signals from the machines.

Who is it for?

The module is intended for production managers and department operators.

What need does it meet?

Thanks to this module, the factory is always under control: simple and intuitive layouts that are completely configurable by user or user profile, make it possible to deliver real-time status updates.

NET@PRO makes available in real-time all progress data, final timings and costs, materials collected and used, the actual location of the material and the WIP.

What are the benefits?

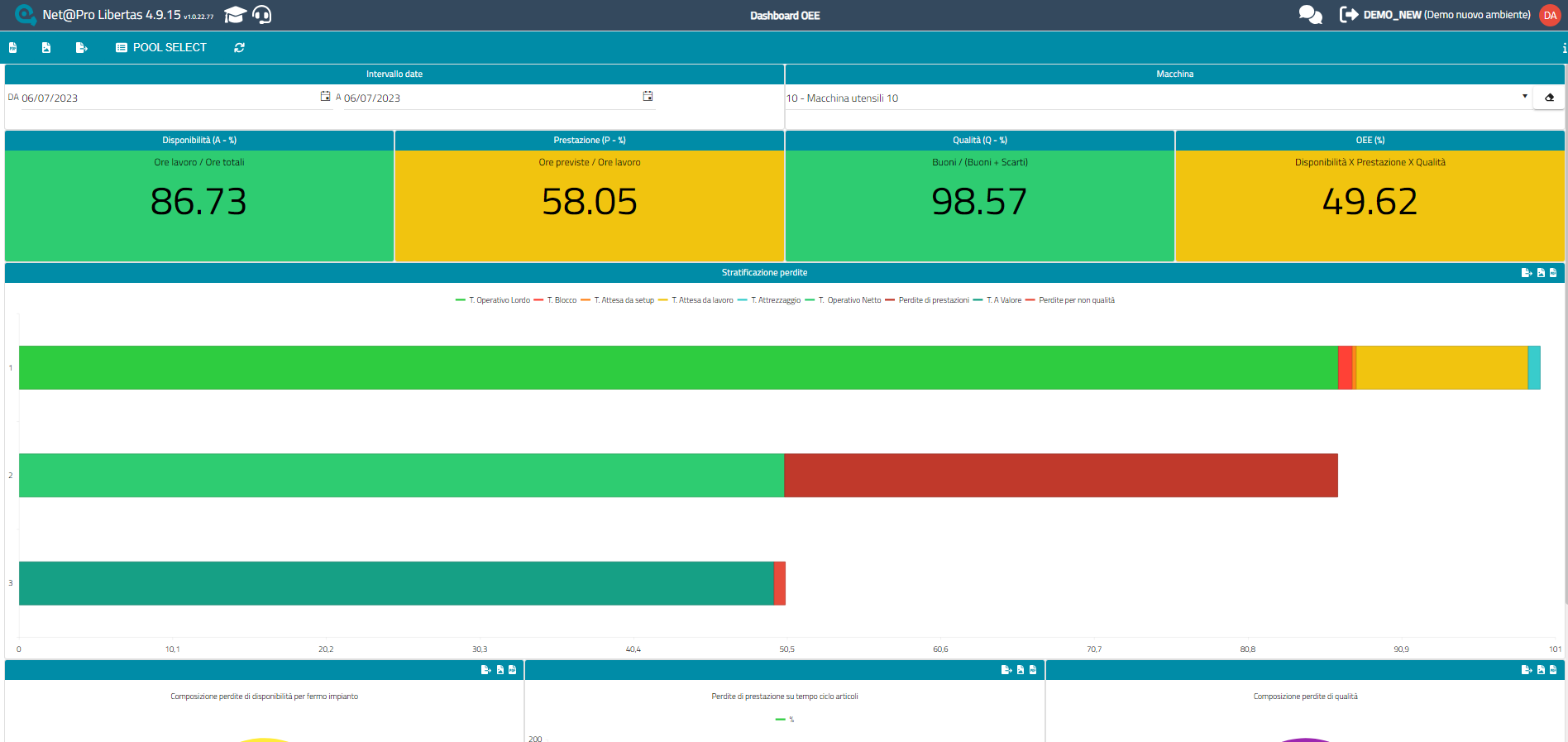

- Precise calculation of the production facility's performance indexes

- Real-time reporting of issues to allow them to be corrected

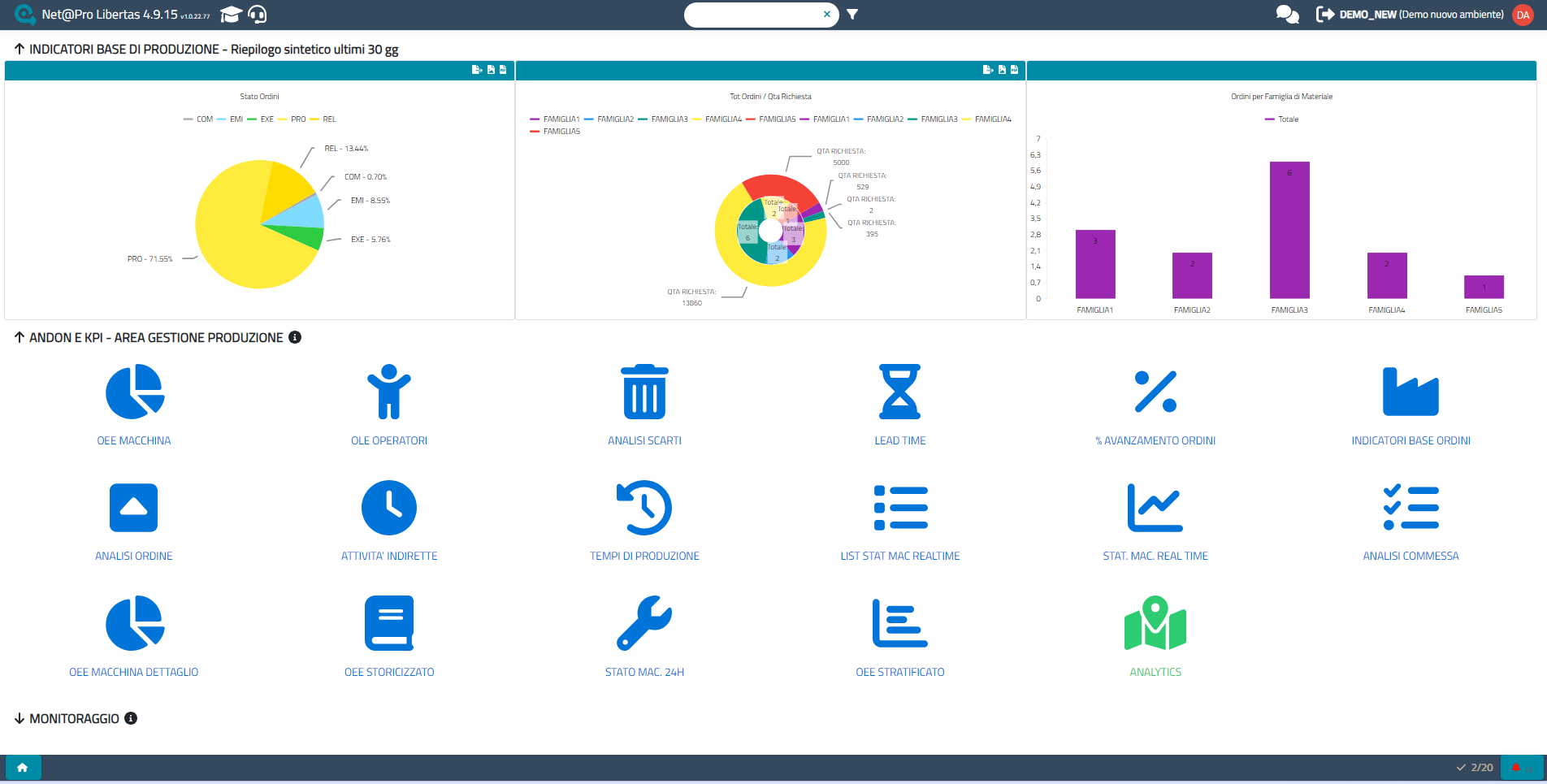

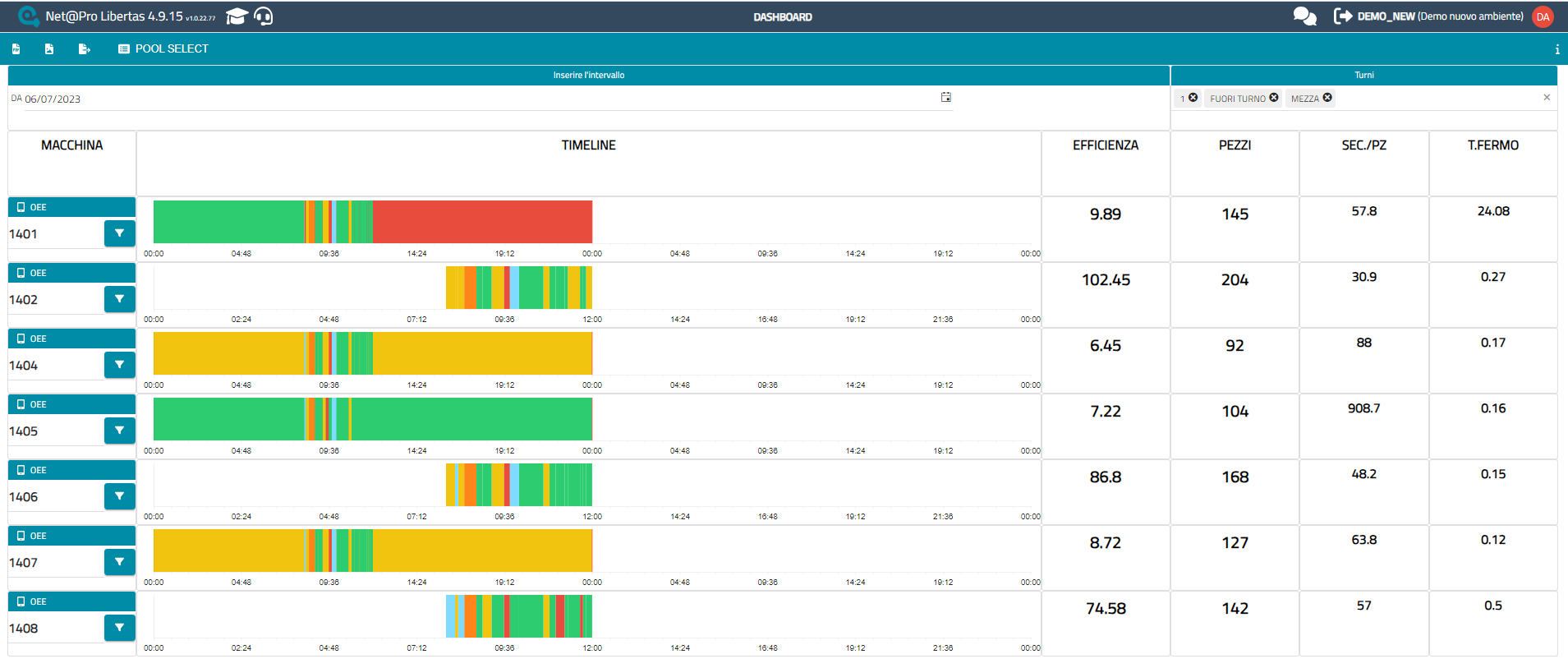

The Production Dashboard lets you constantly monitor the production floor in real time, make the right decisions at the right moment to ensure that the expected results are achieved, and react faster to unforeseen events thus minimizing any loss in operation. Also, it immediately identifies behaviors and issues: tachometers, hystograms, traffic lights, alarms, grids and labels that provide a graphic and intuitive summary of how production is progressing.

In particular, the browsable graphic dashboards use on-screen meters to summarize the numerous detailed data collected by NET@PRO, so you can always be up-to-speed with what is happening in production.

Who is it for?

The module is intended for production managers and department operators.

What need does it meet?

The Production Dashboard makes it possible to constantly monitor the production floor in real time, make the right decisions at the right moment to ensure that the expected results are achieved, and react faster to unforeseen events thus minimizing any loss in operation. Also, it immediately identifies behaviors and issues: tachometers, hystograms, traffic lights, alarms, grids and labels that provide a graphic and intuitive summary of the production in progress.

In particular, the browsable graphic dashboards use on-screen meters to summarize the numerous detailed data collected by NET@PRO, making it possible to always be up-to-speed with what is happening in production.

What are the benefits?

Ensures that operational targets are achieved

Reduction in operational costs

Constant monitoring of the production floor

Faster reaction to unforeseen situations

Containment of operating costs

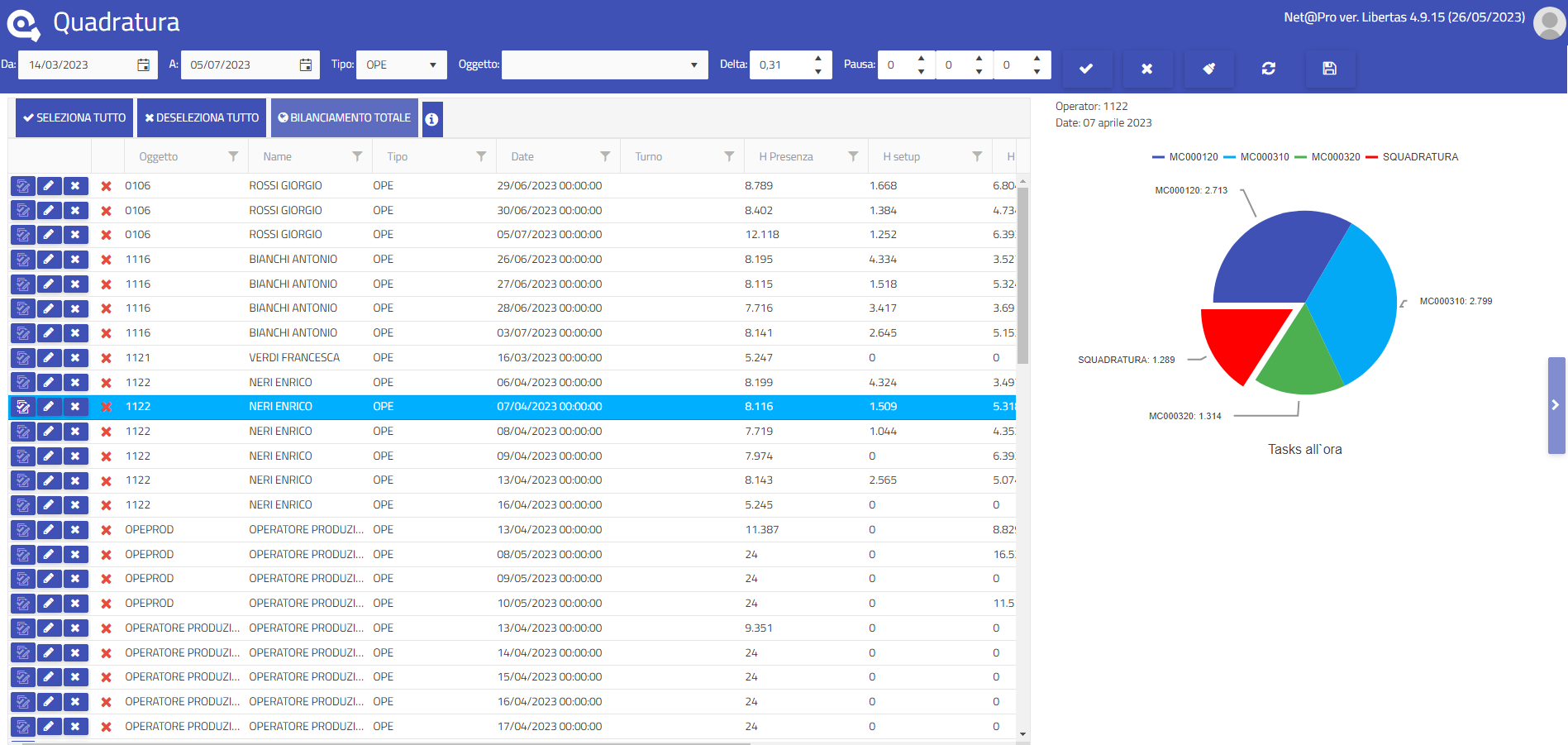

NET@PRO production data collection

With the NET@PRO Production MES, industrial production data is collected completely and correctly, thus rendering the process paperless.

Production progress declarations are done via PC, tablet and smartphone using a web browser or app, making activities data available in real time.

Who is it for?

The module is intended for production managers and department operators.

What need does it meet?

Production data collection is key to being competitive in the marketplace.

With the NET@PRO MES, the declarations collected in real time by the operators or work teams are checked and processed online, providing final square data sorted according to direct and indirect activities, good quantities, rejects and non-conforming/suspended items.

NET@PRO manages production orders and data base data, acquiring it directly from the ERP or through direct entry. It electronically distributes the production plan and all the information regarding the production process (orders, operations, materials, batches, drawings, controls, operating notes, etc.) to the department, providing all information at the right time and in the right place. The system records the progress status of the production orders in real time, eliminating the need to fill and enter hard-copy paperwork at the end of the day. Also, it detects operations and relative times in the event of not clearly defined production cycles or during the construction of prototypes. For parts the require reworking, it automatically generates resumption cycles preserving the link with the original production order.

What are the benefits?

- Accuracy of collected data

- Automation of the progress data collection process

- Increases operator productivity

- Precise definition of production costs

- Drastically reduces errors caused by information that is missing, incorrect or not up to date

- Standard: based on bill of material and work cycle data.

- Forecast: based on production orders to be fulfilled.

- Actual: based on fulfilled production orders. In this case you can also have WIP (work in progress) costs for partially advanced orders.

Who is it for?

It is a cross-level module that speaks to different company roles: from the production manager to the plant manager, the entrepreneur and the controller.

What need does it meet?

It keeps the cost of production under control by analyzing its basic components (direct and indirect, fixed and variable costs) to reduce its complexity and analysis variability.

What are the benefits?

The availability of the right tool for controlling and carefully managing production costs in order to achieve maximum profit for every product made and the possibility to develop stategic actions and make the right decisions more quickly and effectively.

A series of dashboards will provide an immediate overview of the factory system performance.

Request information

Our specialized Qualitas team is here to provide expert advice and a free checkup to improve your company's productivity with a NET@PRO MES software demo and a functional analysis of the production flow.

Complete the form or write to ufficiomarketing@qualitas.it or call

+39 0445 641844